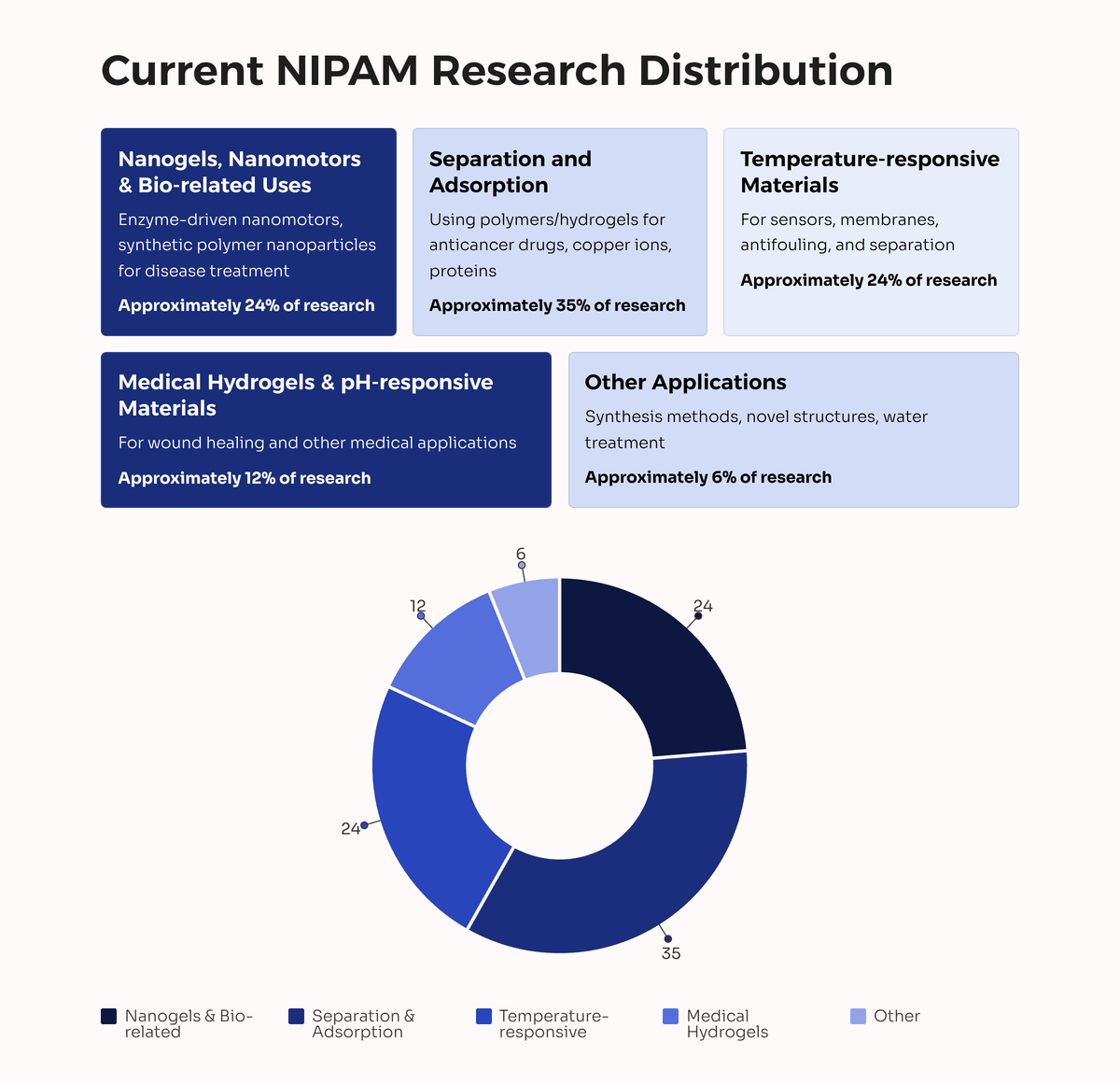

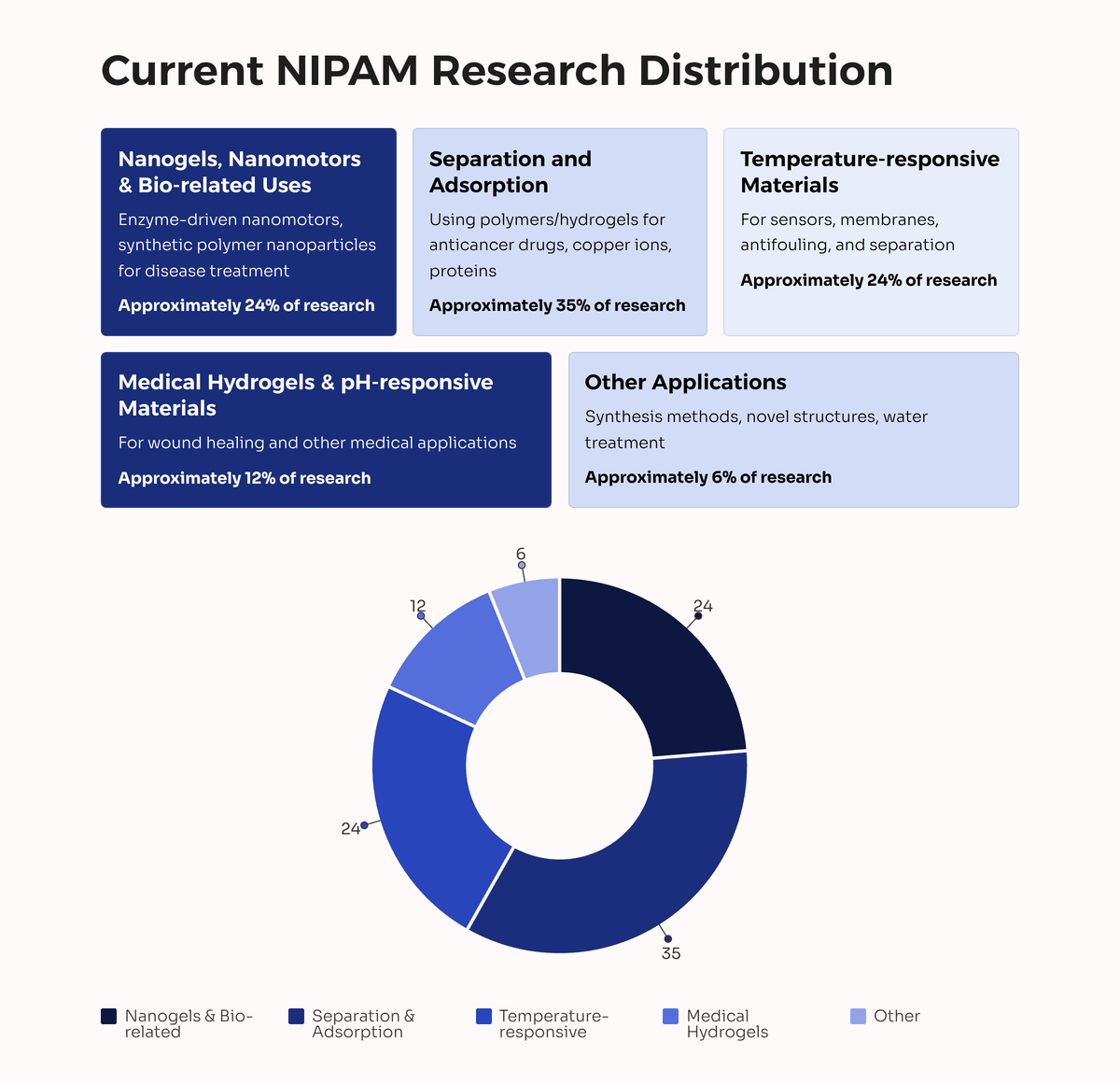

A review of 17 academic papers published in August 2025 reveals the following distribution of NIPAM-related applications:

- Nanogels, nanomotors, drug delivery, and bio-related uses (e.g., enzyme-driven nanomotors, synthetic polymer nanoparticles for disease treatment): approx. 24%

- Separation and adsorption using polymers/hydrogels (e.g., anticancer drugs, copper ions, proteins): approx. 35%

- Temperature-responsive materials for sensors, membranes, antifouling, and separation: approx. 24%

- Medical hydrogels for wound healing and pH-responsive materials: approx. 12%

- Other (e.g., synthesis methods, novel structures, water treatment): approx. 6%

These findings indicate that NIPAM is primarily applied in biomedical and biofunctional nanomaterials, with active research also underway in temperature-responsive sensors and membrane technologies.

Below, we introduce two representative studies and propose potential applications of NIPAM-based materials.

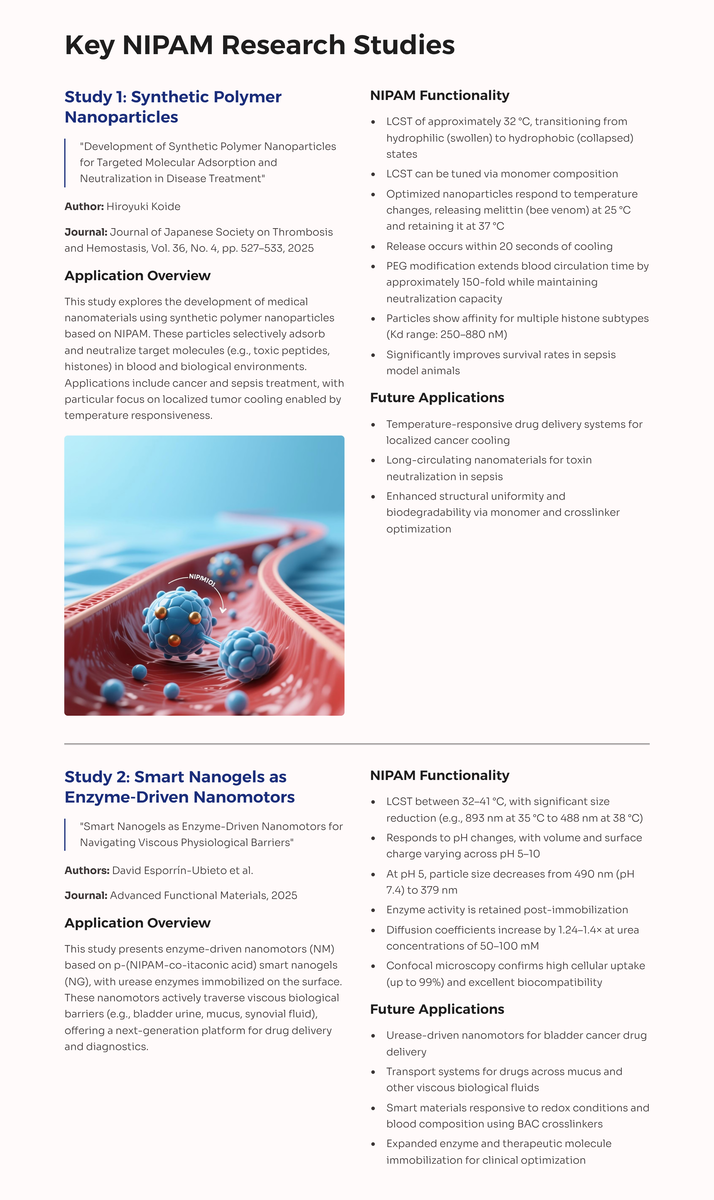

Study 1

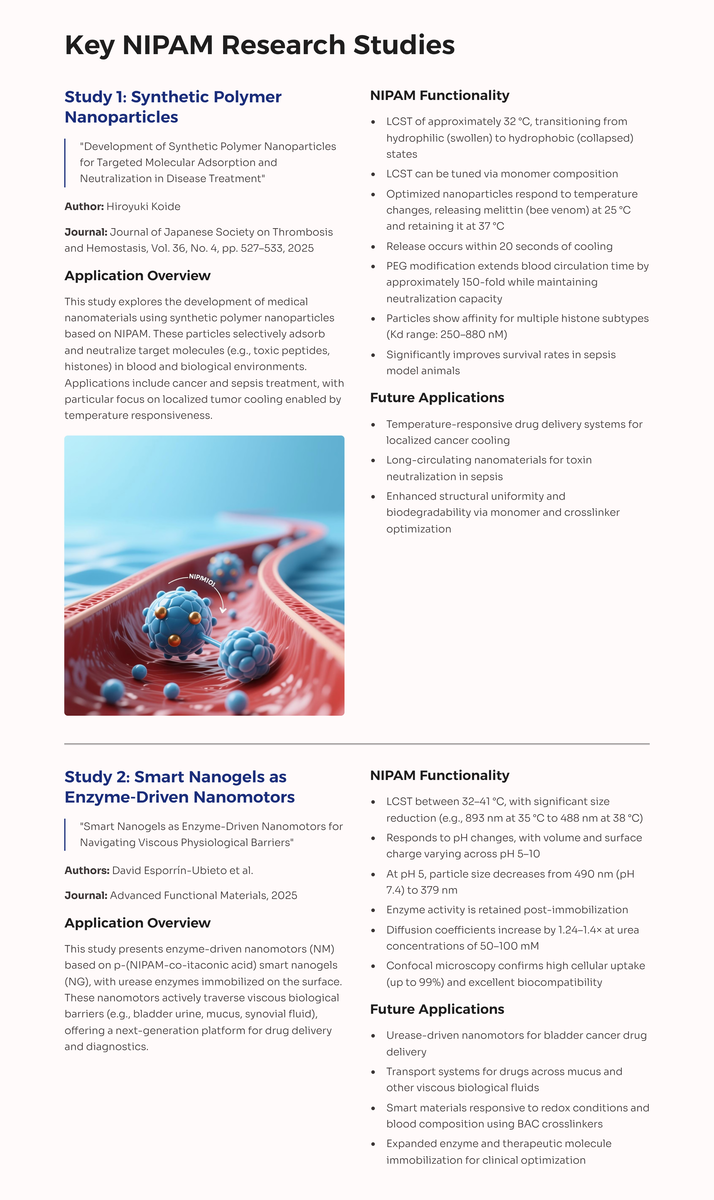

Title: “Development of Synthetic Polymer Nanoparticles for Targeted Molecular Adsorption and Neutralization in Disease Treatment” Author: Hiroyuki Koide Journal: Journal of Japanese Society on Thrombosis and Hemostasis, Vol. 36, No. 4, pp. 527–533, 2025

Application Overview This study explores the development of medical nanomaterials using synthetic polymer nanoparticles based on NIPAM. These particles selectively adsorb and neutralize target molecules (e.g., toxic peptides, histones) in blood and biological environments. Applications include cancer and sepsis treatment, with particular focus on localized tumor cooling enabled by temperature responsiveness.

NIPAM Functionality NIPAM exhibits a lower critical solution temperature (LCST) of approximately 32 °C, transitioning from hydrophilic (swollen) to hydrophobic (collapsed) states. LCST can be tuned via monomer composition. Optimized nanoparticles respond to temperature changes, releasing melittin (bee venom) at 25 °C and retaining it at 37 °C. Release occurs within 20 seconds of cooling.

PEG modification extends blood circulation time by approximately 150-fold while maintaining neutralization capacity. The particles show affinity for multiple histone subtypes (Kd range: 250–880 nM), significantly improving survival rates in sepsis model animals.

Future Applications and Recommendations

- Temperature-responsive drug delivery systems for localized cancer cooling

- Long-circulating nanomaterials for toxin neutralization in sepsis

- Enhanced structural uniformity and biodegradability via monomer and crosslinker optimization

Study 2

Title: “Smart Nanogels as Enzyme-Driven Nanomotors for Navigating Viscous Physiological Barriers” Authors: David Esporrín-Ubieto et al. Journal: Advanced Functional Materials, 2025

Application Overview This study presents enzyme-driven nanomotors (NM) based on p-(NIPAM-co-itaconic acid) smart nanogels (NG), with urease enzymes immobilized on the surface. These nanomotors actively traverse viscous biological barriers (e.g., bladder urine, mucus, synovial fluid), offering a next-generation platform for drug delivery and diagnostics.

NIPAM Functionality The NGs exhibit LCST between 32–41 °C, with significant size reduction (e.g., 893 nm at 35 °C to 488 nm at 38 °C). They also respond to pH changes, with volume and surface charge varying across pH 5–10. At pH 5, particle size decreases from 490 nm (pH 7.4) to 379 nm. Enzyme activity is retained post-immobilization, and diffusion coefficients increase by 1.24–1.4× at urea concentrations of 50–100 mM. Confocal microscopy confirms high cellular uptake (up to 99%) and excellent biocompatibility.

Future Applications and Recommendations

- Urease-driven nanomotors for bladder cancer drug delivery

- Transport systems for drugs across mucus and other viscous biological fluids

- Smart materials responsive to redox conditions and blood composition using BAC crosslinkers

- Expanded enzyme and therapeutic molecule immobilization for clinical optimization

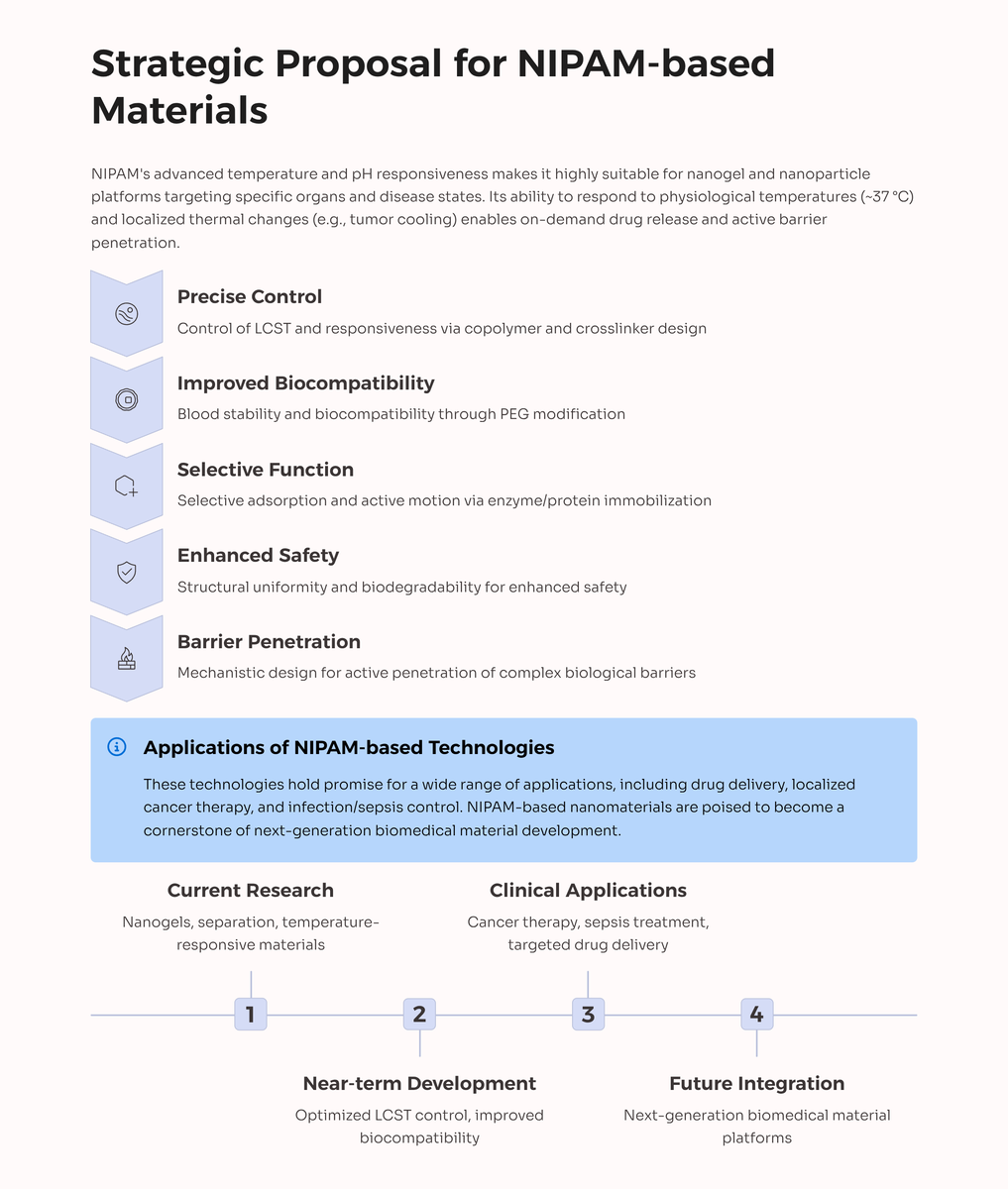

Strategic Proposal

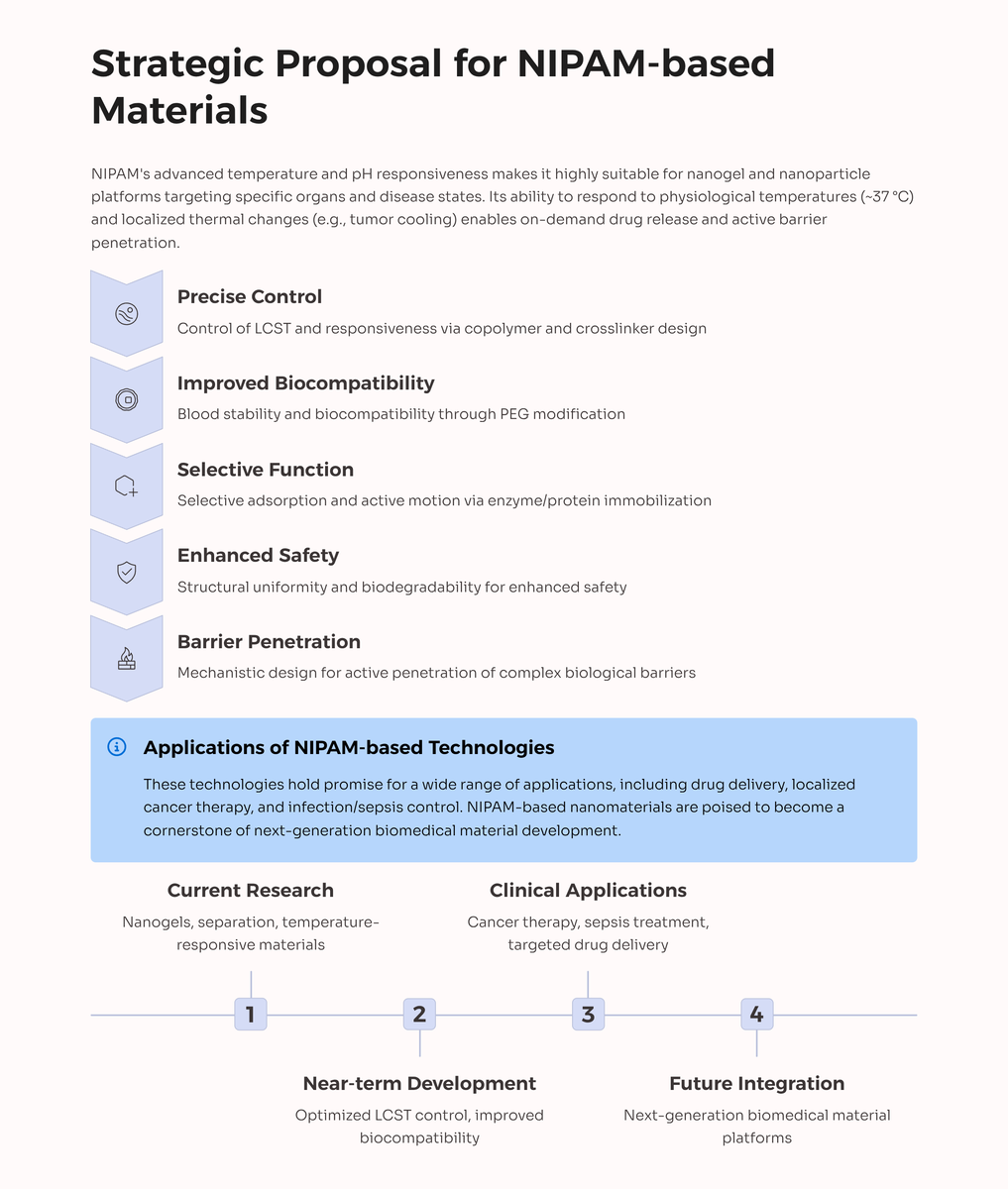

NIPAM’s advanced temperature and pH responsiveness makes it highly suitable for nanogel and nanoparticle platforms targeting specific organs and disease states. Its ability to respond to physiological temperatures (~37 °C) and localized thermal changes (e.g., tumor cooling) enables on-demand drug release and active barrier penetration.

Recommended Development Focus Areas:

- Precise control of LCST and responsiveness via copolymer and crosslinker design

- Improved blood stability and biocompatibility through PEG modification

- Selective adsorption and active motion via enzyme/protein immobilization

- Structural uniformity and biodegradability for enhanced safety

- Mechanistic design for active penetration of complex biological barriers

These technologies hold promise for a wide range of applications, including drug delivery, localized cancer therapy, and infection/sepsis control. NIPAM-based nanomaterials are poised to become a cornerstone of next-generation biomedical material development.

Reference

- Esporrín‐Ubieto, David 他, "Smart Nanogels as Enzyme‐Driven Nanomotors for Navigating Viscous Physiological Barriers", Advanced Functional Materials, 2025, Wiley Online Library, e10203

- Zeb, Umar 他, "Targeted quercetin extraction from cherry and strawberry juices via chitosan-modified macroporous monolith", Journal of Molecular Structure, 2025, Elsevier, 143723

- Yawen, Tian 他, "One Dual Stimulus Response Molecular Imprinted Hydrogel for Specific Recognition and Enrichment of Doxorubicin", Journal of Separation Science, 48(8), 2025, Wiley Online Library, e70249

- 小出裕之, "標的分子を吸着・中和する合成高分子ナノ粒子を用いた疾患治療への挑戦", 日本血栓止血学会誌, 36(4), 2025, 一般社団法人 日本血栓止血学会, 527-533

- Yang, Lian 他, "Effect of Performance and Fouling Mechanisms of Thermo-Responsive Membranes on Treating Secondary Effluent Containing Added Sulfamethoxazole", Separations, 2025, MDPI

- Zhong, Qing 他, "A Mechanical Contraction‐Driven Hydrogel Dressing for pH Visualization and Tailored Acute/Chronic Wound Healing", Advanced Functional Materials, 2025, Wiley Online Library, e12807

- Khouzania, Nasim Salmani 他, "Synthesis of silica nanoparticles grafted with copolymer of nipam-acrylic acid for removal of methylene blue from aquatic solutions", 2025

- Tang, Qichen 他, "Double Response Composite Hydrogel With Large Reverse Bending Properties", Journal of Applied Polymer Science, 2025, Wiley Online Library, e57816

- Shiva Samhitha, Saireddy, "Molecularly imprinted polymers synthesized on a rigid substrate as a solid phase coupled with sers for detection of prostate cancer biomarker.", 2025, Universidad de Concepción

- Hu, Zhenyu 他, "Thermo-driven “Molecular Wipers” for anti-protein adhesion of bioethanol immobilized fermentation", Chemical Engineering Journal, 2025, Elsevier, 167040

- Li, Zhikun 他, "Preparation of Sodium Alginate-Based Temperature-and Ph-Responsive Mof/Hydrogel Microspheres and Their Adsorption and Separation of Proteins", 2025

- Fan, Jiashen 他, "Tunable and Environmental-Adaptive Ionogel Sensors with High Adhesion and Broad-Range Thermal Responsiveness", 2025

- Tavagnacco, Letizia 他, "Thermoresponsive copolymer microgels synthesized via single-step precipitation polymerization: random or block structure?", arXiv preprint arXiv:2508.04246, 2025

- Yang, Lian 他, "Effect of the Composition of Pvdf-Nipam-Go Membrane for the Removal of Organic Contaminant and Anti-Fouling from Biofilter Effluent Under the Responsible Temperature", SSRN 5379261, 2025

- Gao, Yuan 他, "A novel fabrication method for gradient-structured PNIPAM-based hydrogels", Journal of Physics: Conference Series, 3068(1), 2025, IOP Publishing, 012105

- Fan, Jingyi 他, "Temperature-responsive AuNPs/poly (N-isopropylacrylamide) hydrogel-based sensor for SERS detection of paraquat in fruit juices", Microchimica Acta, 192(8), 2025, Springer

- Rogić Miladinović, Zorana 他, "Efficient Copper Ion Removal from Wastewater Using Copolymeric Hydrogels Based on NIPAM, OEGMA, and Acids Synthesized via Gamma Radiation", ICARST-2025 Book of Abstracts, 2025, IAEA, 402